SUBTITLE G: WASTE DISPOSAL

CHAPTER I: POLLUTION CONTROL BOARD

SUBCHAPTER c: HAZARDOUS WASTE OPERATING REQUIREMENTS

PART 721 IDENTIFICATION AND LISTING OF HAZARDOUS WASTE

SECTION 721.983 MATERIAL DETERMINATION PROCEDURES

Section 721.983 Material Determination Procedures

a) Procedure to Determine Average Volatile Organic (VO) Concentration

1) Determining average VO concentration at the point of material origination. A remanufacturer or other person that stores or treats the hazardous secondary material must determine the average VO concentration at the point of material origination for each hazardous secondary material placed in a hazardous secondary material management unit exempted under the provisions of Section 721.982(c) from using air emission controls in compliance with standards specified in Sections 721.984 through 721.987, as applicable to the hazardous secondary material management unit.

A) An initial determination of the average VO concentration of the material stream must be made before the first time any portion of the material in the hazardous secondary material stream is placed in a hazardous secondary material management unit exempted under the provisions of Section 721.982(c) from using air emission controls, and thereafter an initial determination of the average VO concentration of the material stream must be made for each averaging period that a hazardous secondary material is managed in the unit; and

B) Perform a new material determination whenever changes to the source generating the material stream are reasonably likely to cause the average VO concentration of the hazardous secondary material to increase to a level that is equal to or greater than the applicable VO concentration limits specified in Section 721.982.

2) Determining average VO concentration using direct measurement or knowledge. For a material determination that is required by subsection (a)(1), the average VO concentration of a hazardous secondary material at the point of material origination must be determined using either direct measurement, as specified in subsection (a)(3), or by knowledge of the hazardous secondary material, as specified in subsection (a)(4).

3) Direct measurement to determine average VO concentration of a hazardous secondary material at the point of material origination, as follows:

A) Identification. The remanufacturer or other person that stores or treats the hazardous secondary material must identify and record in a log that is kept at the facility the point of material origination for the hazardous secondary material.

B) Sampling. Samples of the hazardous secondary material stream must be collected at the point of material origination in a manner so that volatilization of organics contained in the material and in the subsequent sample is minimized and an adequately representative sample is collected and maintained for analysis by the selected method.

i) The averaging period to be used for determining the average VO concentration for the hazardous secondary material stream on a mass-weighted average basis must be designated and recorded. The averaging period can represent any time interval that the remanufacturer or other person that stores or treats the hazardous secondary material determines is appropriate for the hazardous secondary material stream but must not exceed one year.

ii) Enough samples, but at least four, must be collected and analyzed for a hazardous secondary material determination. The samples for a given material determination must be collected within a one-hour period. The average of the four or more sample results constitutes a material determination for the material stream. One or more material determinations may be required to represent the complete range of material compositions and quantities that occur during the entire averaging period due to normal variations in the operating conditions for the source or process generating the hazardous secondary material stream. Examples of these normal variations are seasonal variations in material quantity or fluctuations in ambient temperature.

iii) All samples must be collected and handled according to written procedures prepared by the remanufacturer or other person that stores or treats the hazardous secondary material and documented in a site sampling plan. This plan must describe the procedure by which representative samples of the hazardous secondary material stream are collected so that a minimum loss of organics occurs throughout the sample collection and handling process, and by which sample integrity is maintained. A copy of the written sampling plan must be maintained at the facility. An example of acceptable sample collection and handling procedures for a total volatile organic constituent concentration may be found in Reference Method 25D (Determination of the Volatile Organic Concentration of Waste Samples) in appendix A to 40 CFR 60 (Test Methods), incorporated by reference in 35 Ill. Adm. Code 720.111.

iv) Sufficient information, as specified in the "site sampling plan" required under subsection (a)(3)(B)(iii), must be prepared and recorded to document the material quantity represented by the samples and, as applicable, the operating conditions for the source or process generating the hazardous secondary material represented by the samples.

C) Analysis. Each collected sample must be prepared and analyzed according to Reference Method 25D (Determination of the Volatile Organic Concentration of Waste Samples) in appendix A to 40 CFR 60 (Test Methods), incorporated by reference in 35 Ill. Adm. Code 720.111, for the total concentration of volatile organic constituents, or using one or more methods when the individual organic compound concentrations are identified and summed and the summed material concentration accounts for and reflects all organic compounds in the material with Henry's law constant values at least 0.1 mole-fraction-in-the-gas-phase/mole-fraction-in-the-liquid-phase (0.1 Y/X) (which can also be expressed as 1.8 × 10-6 atmospheres/gram-mole/m3) at 25 ºC. At the discretion of the remanufacturer or other person that stores or treats the hazardous secondary material, the test data obtained may be adjusted by any appropriate method to discount any contribution to the total volatile organic concentration that is a result of including a compound with a Henry's law constant value of less than 0.1 Y/X at 25 °C. To adjust these data, the measured concentration of each individual chemical constituent contained in the material is multiplied by the appropriate constituent-specific adjustment factor (fm25D). If the remanufacturer or other person that stores or treats the hazardous secondary material elects to adjust the test data, the adjustment must be made to all individual chemical constituents with a Henry's law constant value greater than or equal to 0.1 Y/X at 25 ºC contained in the material. To adjust these data, the measured concentration of each individual chemical constituent contained in the waste is multiplied by the constituent-specific adjustment factors (fm25D) approved in writing by the Agency. Other test methods may be used if they meet the requirements in subsection (a)(3)(C)(i) or (a)(3)(C)(ii) and provided the requirement to reflect all organic compounds in the material with Henry's law constant values greater than or equal to 0.1 Y/X (which can also be expressed as 1.8 × 10-6 atmospheres/gram-mole/m3) at 25 ºC, is met.

i) Any USEPA standard method that has been validated in compliance with appendix D to 40 CFR 63 (Alternative Validation Procedure for EPA Waste and Wastewater Methods), incorporated by reference in 35 Ill. Adm. Code 720.111.

ii) Any other analysis method that has been validated in according to the procedures specified in Section 5.1 or Section 5.3, and the corresponding calculations in Section 6.1 or Section 6.3, of Method 301 (Field Validation of Pollutant Measurement Methods from Various Waste Media) in appendix A to 40 CFR 63 (Test Methods), incorporated by reference in 35 Ill. Adm. Code 720.111. The data are acceptable if they meet the criteria specified in Section 6.1.5 or Section 6.3.3 of Method 301. If correction is required under section 6.3.3 of Method 301, the data are acceptable if the correction factor is within the range 0.7 to 1.30. Other sections of Method 301 are not required.

D) Calculations

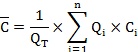

i) The

average VO concentration (![]() )

on a mass-weighted basis must be calculated by using the results for all

material determinations conducted in compliance with subsections (a)(3)(B) and

(a)(3)(C) and the following equation:

)

on a mass-weighted basis must be calculated by using the results for all

material determinations conducted in compliance with subsections (a)(3)(B) and

(a)(3)(C) and the following equation:

Where:

|

|

= |

Average VO concentration of the hazardous secondary material at the point of material origination on a mass-weighted basis, ppmw |

|

i |

= |

Individual material determination "i" of the hazardous secondary material |

|

n |

= |

Total number of material determinations of the hazardous secondary material conducted for the averaging period (not to exceed one year) |

|

Qi |

= |

Mass quantity of hazardous secondary material stream represented by Ci, kg/hr |

|

QT |

= |

Total mass quantity of hazardous secondary material during the averaging period, kg/hr |

|

Ci |

= |

Measured VO concentration of material determination "i" as determined in compliance with subsection (a)(3)(C) (i.e., the average of the four or more samples specified in subsection (a)(3)(B)(ii)), ppmw |

ii) For determining Ci, for individual material samples analyzed in compliance with subsection (a)(3)(C), the remanufacturer or other person that stores or treats the hazardous secondary material must account for VO concentrations determined to be below the detection limit of the analytical method by using the VO concentration that is one-half the blank value determined in the method at section 4.4 of Reference Method 25D, if Reference Method 25D is used for the analysis; or that is one-half the sum of the limits of detection established for each organic constituent in the material that has a Henry's law constant values at least 0.1 mole-fraction-in-the-gas-phase/mole-fraction-in-the-liquid-phase (0.1 Y/X) (which can also be expressed as 1.8 × 10‑6 atmospheres/gram-mole/m3) at 25 °C, if any other analytical method is used.

4) Use of knowledge by the remanufacturer or other person that stores or treats the hazardous secondary material to determine average VO concentration of a hazardous secondary material at the point of material origination.

A) Documentation must be prepared that presents the information used as the basis for the knowledge by the remanufacturer or other person that stores or treats the hazardous secondary material of the hazardous secondary material stream's average VO concentration. Examples of information that may be used as the basis for knowledge include material balances for the source or process generating the hazardous secondary material stream; constituent-specific chemical test data for the hazardous secondary material stream from previous testing that are still applicable to the current material stream; previous test data for other locations managing the same type of material stream; or other knowledge based on information included in shipping papers or material certification notices.

B) If test data are used as the basis for knowledge, then the remanufacturer or other person that stores or treats the hazardous secondary material must document the test method, sampling protocol, and the means by which sampling variability and analytical variability are accounted for in determining the average VO concentration. For example, a remanufacturer or other person that stores or treats the hazardous secondary material may use organic concentration test data for the hazardous secondary material stream that are validated according to Method 301 (Field Validation of Pollutant Measurement Methods from Various Waste Media) in appendix A to 40 CFR 63 (Test Methods) as the basis for knowledge of the material.

C) A remanufacturer or other person that stores or treats the hazardous secondary material using chemical constituent-specific concentration test data as the basis for knowledge of the hazardous secondary material may adjust the test data to the corresponding average VO concentration value that would have been obtained had the material samples been analyzed using Reference Method 25D (Determination of the Volatile Organic Concentration of Waste Samples) in appendix A to 40 CFR 60 (Test Methods), incorporated by reference in 35 Ill. Adm. Code 720.111(b). To adjust these data, the measured concentration for each individual chemical constituent contained in the material is multiplied by the appropriate constituent-specific adjustment factor (fm25D).

D) In the event that the Agency and the remanufacture or other person that stores or treats the hazardous secondary material disagree on a determination of the average VO concentration for a hazardous secondary material stream using knowledge, then the results from a determination of average VO concentration using direct measurement, as specified in subsection (a)(3), must be used to establish compliance with the applicable requirements of this Subpart CC. The Agency may perform or request that the remanufacturer or other person that stores or treats the hazardous secondary material perform this determination using direct measurement. The remanufacturer or other person that stores or treats the hazardous secondary material may choose one or more appropriate methods to analyze each collected sample under subsection (a)(3)(C). The Agency must state any disagreement on determination of the average VO concentration for a hazardous secondary material stream using knowledge in writing to the remanufacturer or other person that stores or treats the hazardous secondary material.

b) This subsection (b) corresponds with 40 CFR 261.1083(b), marked "reserved" by USEPA. This statement maintains structural consistency with the federal regulations.

c) Procedure to Determine the Maximum Organic Vapor Pressure of a Hazardous Secondary Material in a Tank

1) A remanufacturer or other person that stores or treats the hazardous secondary material must determine the maximum organic vapor pressure for each hazardous secondary material placed in a tank using Tank Level 1 controls in compliance with standards specified in Section 721.984(c).

2) A remanufacturer or other person that stores or treats the hazardous secondary material must use either direct measurement as specified in subsection (c)(3) or knowledge of the waste as specified by subsection (c)(4) to determine the maximum organic vapor pressure that is representative of the hazardous secondary material composition stored or treated in the tank.

3) Direct Measurement to Determine the Maximum Organic Vapor Pressure of a Hazardous Secondary Material

A) Sampling. Enough samples must be collected to be representative of the hazardous secondary material contained in the tank. All samples must be collected and handled according to written procedures prepared by the remanufacturer or other person that stores or treats the hazardous secondary material and documented in a site sampling plan. This plan must describe the procedure by which representative samples of the hazardous secondary material are collected so that a minimum loss of organics occurs throughout the sample collection and handling process and by which sample integrity is maintained. A copy of the written sampling plan must be maintained at the facility. An example of acceptable sample collection and handling procedures may be found in Reference Method 25D (Determination of the Volatile Organic Concentration of Waste Samples) in appendix A to 40 CFR 60 (Test Methods), incorporated by reference in 35 Ill. Adm. Code 720.111(b).

B) Analysis. Any appropriate one of the following methods may be used to analyze the samples and compute the maximum organic vapor pressure of the hazardous secondary material:

i) Reference Method 25E (Determination of Vapor Phase Organic Concentration in Waste Samples) in appendix A to 40 CFR 60 (Test Methods), incorporated by reference in 35 Ill. Adm. Code 720.111(b);

ii) Methods described in American Petroleum Institute Publication 2517, Third Edition, February 1989, "Evaporative Loss from External Floating-Roof Tanks", incorporated by reference in 35 Ill. Adm. Code 720.111;

iii) Methods obtained from standard reference texts;

iv) ASTM Method 2879-92, incorporated by reference in 35 Ill. Adm. Code 720.111; and

v) Any other method approved in writing by the Agency.

4) Use of Knowledge to Determine the Maximum Organic Vapor Pressure of the Hazardous Secondary Material. Documentation must be prepared and recorded that presents the information used as the basis for the knowledge by the remanufacturer or other person that stores or treats the hazardous secondary material that the maximum organic vapor pressure of the hazardous secondary material is less than the maximum vapor pressure limit listed in Section 721.984(b)(1)(A) for the applicable tank design capacity category. An example of information that may be used is documentation that the hazardous secondary material is generated by a process for which at other locations it previously has been determined by direct measurement that the hazardous secondary material's waste maximum organic vapor pressure is less than the maximum vapor pressure limit for the appropriate tank design capacity category.

d) Procedure for Determining No Detectable Organic Emissions for the Purpose of Complying with this Subpart CC

1) The test must be conducted according to the procedures specified in Reference Method 21 (Determination of Volatile Organic Compound Leaks) in appendix A to 40 CFR 60 (Test Methods), incorporated by reference in 35 Ill. Adm. Code 720.111. Each potential leak interface (i.e., a location if organic vapor leakage could occur) on the cover and associated closure devices must be checked. Potential leak interfaces that are associated with covers and closure devices include the interface of the cover and its foundation mounting, the periphery of any opening on the cover and its associated closure device, and the sealing seat interface on a spring-loaded pressure relief valve.

2) The test must be performed when the unit contains a hazardous secondary material having an organic concentration representative of the range of concentrations for the hazardous secondary material expected to be managed in the unit. During the test, the cover and closure devices must be secured in the closed position.

3) The detection instrument must meet the performance criteria of Reference Method 21, except the instrument response factor criteria in section 3.1.2(a) of Reference Method 21, must be for the average composition of the organic constituents in the hazardous secondary material placed in the hazardous secondary management unit, not for each individual organic constituent.

4) The detection instrument must be calibrated before use on each day of its use by the procedures specified in Reference Method 21.

5) Calibration gases must be as follows:

A) Zero air (less than 10 ppmv hydrocarbon in air); and

B) A mixture of methane or n-hexane and air at a concentration of approximately, but less than, 10,000 ppmv methane or n-hexane.

6) The background level must be determined according to the procedures in Reference Method 21.

7) Each potential leak interface must be checked by traversing the instrument probe around the potential leak interface as close to the interface as possible, as described in Reference Method 21. If the configuration of the cover or closure device prevents a complete traverse of the interface, all accessible portions of the interface must be sampled. If the configuration of the closure device prevents any sampling at the interface and the device is equipped with an enclosed extension or horn (e.g., some pressure relief devices), the instrument probe inlet must be placed at approximately the center of the exhaust area to the atmosphere.

8) The arithmetic difference between the maximum organic concentration indicated by the instrument and the background level must be compared with the value of 500 ppmv except when monitoring a seal around a rotating shaft that passes through a cover opening, in which case the comparison must be as specified in subsection (d)(9). If the difference is less than 500 ppmv, then the potential leak interface is determined to operate with no detectable organic emissions.

9) For the seals around a rotating shaft that passes through a cover opening, the arithmetic difference between the maximum organic concentration indicated by the instrument and the background level must be compared with the value of 10,000 ppmw. If the difference is less than 10,000 ppmw, then the potential leak interface is determined to operate with no detectable organic emissions.

(Source: Amended at 48 Ill. Reg. 16813, effective November 7, 2024)